When I started working in the car industry with General Motors in 1988, the teams involved in the product development process were very much divided into different silos. Silos existed based on skills, tools, and quality processes. Engineers shared drawings and mass production product information via human networks and rigorous configuration management. Mainframe computers and databases managed the supply chain of parts into the factories.

Decades later when I retired as GM’s PLM Leader, silos still exist despite the promises made by digital transformation tool providers to bring teams together. In fact some digital technologies, especially personal computing and local files/databases, have led to more silos thus fragmenting decision making.

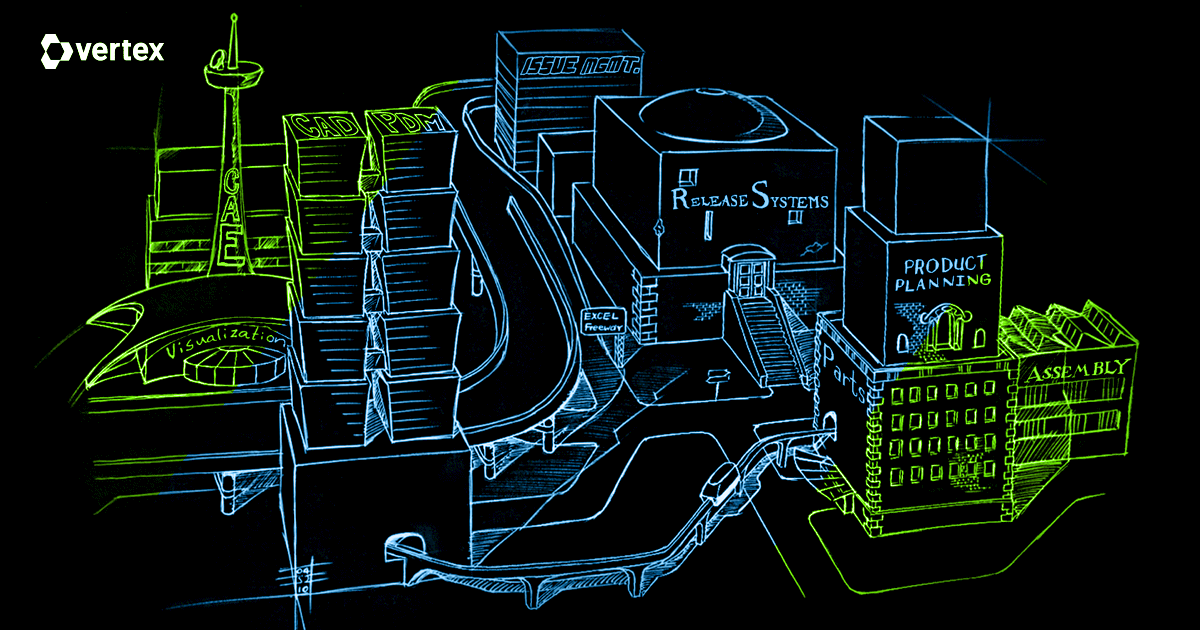

The Manufacturing Cityscape

I relate it back to the image you can see below. This is a cartoon my colleague in Germany drew many years ago. You can see different PDM software suites and CAD solutions in the front, loosely connected to each other. All the computer-aided engineering tools, like simulation and visualization, are across the highway. Manufacturing is off on its own to the right. And of course, there are silos for product planning, parts management, and the supply chain.

It’s probably not a surprise to many readers that some critical connections between these silos were purpose-built, as seen by the monorail connecting engineering tools to manufacturing tools. It’s important then, and now, to transfer 3D geometry into the manufacturing systems. On the other hand, systems for releasing, issues management, and simulation remain in their own islands without direct, automatic access to 3D geometry or product data. Too frequently, the only way people could communicate between the silos is the “Excel Freeway.”

In fact, that’s the whole point that I like about this image. How do we traverse these different silos to make better decisions? Engineers need to confirm your design decisions are valid as you get close to mass production. Companies need to understand how a marketplace has changed. And every entity needs to communicate with everyone in the organization and supply chain.

Digital Transformation Connecting the City

I do believe digital transformation is helping companies easily navigate between the different silos. But it’s still very much an uphill battle. In fact, I was reading a report recently that said only 5 percent of companies who have started a formal digital transformation process are happy with their progress. There’s a lot of reasons that could be the case. Companies may not have a good strategy before they jump in. Maybe they aren’t willing to put the time and cost resources into the effort. Or, they may simply be impatient.

From my perspective, it’s all about how you traverse information amongst different silos. The notion of departmental silos isn’t going anywhere anytime soon. So you have to put your efforts into viewing information around the organization. The Excel Freeway won’t cut it in today’s digital age. You miss too much product data and associated visuals. That’s why I think finding ways to make sure everyone can access a digital twin is a good step in the right direction.

So let’s take some time to talk about the digital twin. Although every company approaches the concept of the digital twin a little bit differently, digital twins give companies business intelligence to make better decisions about their products, which is the whole point of a connected manufacturing cityscape. Here are five examples where I see different digital twins having the most impact.

Digital twins link the physical and digital worlds in real-time.

I think we can all agree that there are major discrepancies between as-designed and as-built documentation. Once a product’s design is passed along to the manufacturing department, there may be changes made to the product without updating the as-designed documentation. Digital twins can create consistency throughout the lifecycle. So, a manufacturing company can use twins to track component variations, inform the next-generation of the product, develop predictive modeling, and diagnose and resolve issues as they occur.

Digital twins drive product quality and innovation.

I touched on this in the last section, but I’d like to dwell on this for a moment. Once a product has been mass produced and is out in use, manufacturers are tracking how every little component performs. Gartner claims that this year, there will be more than 20 billion connected sensors and endpoints. So what does this actually mean? Well, for example, a company can track field data to understand how driving in a flat geography like Nebraska impacts a vehicle’s performance, as opposed to something mountainous like Colorado. Companies can understand how any variable impacts their product’s performance so they know how to make improvements to future versions of the component.

Digital twins give visibility and analytics for continuous improvement.

Let’s continue on this train of thought. Keeping with the same example, let’s say a car company is tracking how a transmission performs in places like Nebraska versus Colorado. Sensor data is feeding back to the company that the transmissions in hillier areas start to lose performance faster. Sure, but exactly how much faster? Digital twins can start to feed into predictive analytics so companies can perform preventative maintenance before part physically fails. Consider what happens when manufacturing equipment like a large wheel loader stops working. It could cost companies thousands, even millions, of dollars in downtime. But fixing a component before it actually fails could eliminate hours or weeks of downtime.

Digital twins connect teams for real-time decision making.

As part of my current consultation, I’ve been working as an executive consultation with CIMdata. There’s one question that catches my eye: “How often does your organization have product issues requiring management attention that are traceable to miscommunication?” The last time I checked, 92 percent of the respondents trace miscommunication as the root cause of problems (no surprise there), and 30 percent of them experienced more than 10 issues a month thanks to miscommunication. My point here is that if we can help to alleviate miscommunications by using digital twins as a source of truth, we may be able to lower this quite a bit. A digital twin gives different silos in your manufacturing cityscape access to the same, real-time visuals and information. That’s pretty powerful.

Digital twins lower costs.

This may go without saying, but let’s consider the four points we’ve discussed leading up to this point. We have connected, up-to-date documentation throughout the product lifecycle. We have insight into how a product performs so we can improve future products. We have predictive analytics so we can get ahead of product issues out in the field. And, we’re alleviating miscommunications. Manufacturers could save millions—even billions—of dollars and hours of time thanks to a digital twin.

What’s next for the manufacturing cityscape?

If my previous colleague at GM were to redo this cartoon today, all the different silos would still be there. But there may be a great deal more monorails or skywalks that connect different silos together through digital tools. What’s missing in the drawing now is some representation of a digital twin that truly connects silos on some kind of two-way street, like a central nervous system.

I think cloud technologies should enable a contextual digital twin to be produced from whatever silos have relevant information, thus improving the context and the quality of decision-making. Today pervasive computing in your palm has given product developers faster information access and visualization techniques. I could even imagine “agents” which could traverse the silos and advise a lead engineer to potential risks, similar to what is done manually today with DFSS (Design For Six Sigma) and FMEA (Failure Modes and Effects Analysis).

COMMENTS